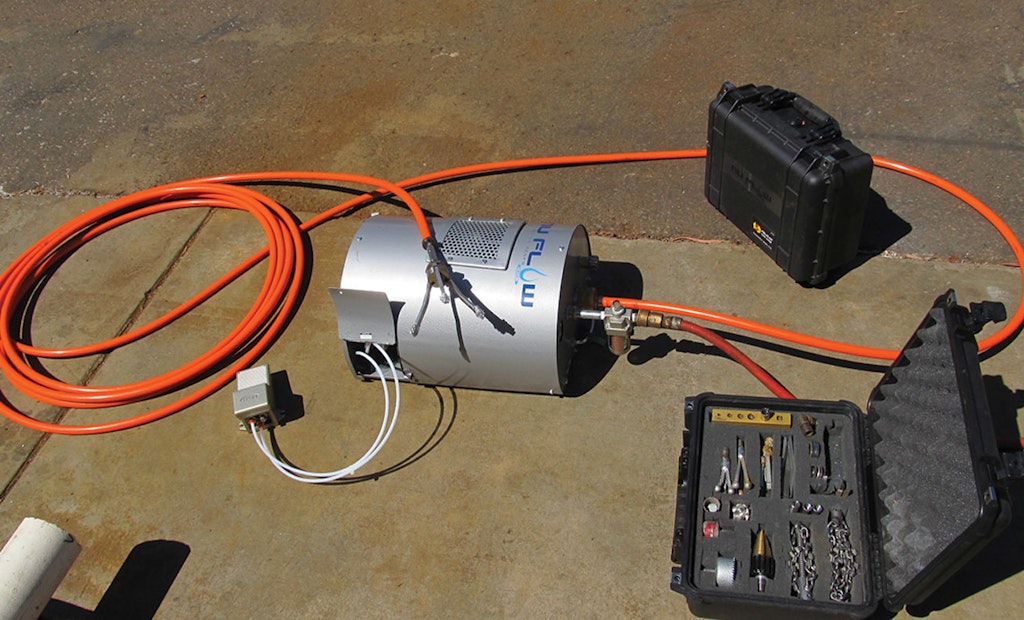

Hot-water jetter used to clean lines in school

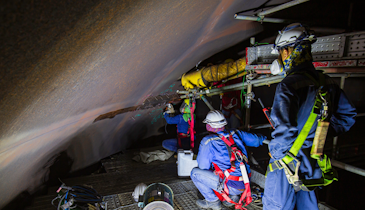

Problem: Dennis Critchfield, owner of Critch’s Sewer Inspection in Hill City, Kansas, was recently called to a middle school lunchroom to camera lines in the kitchen area that were plugging on a monthly basis. He was informed...