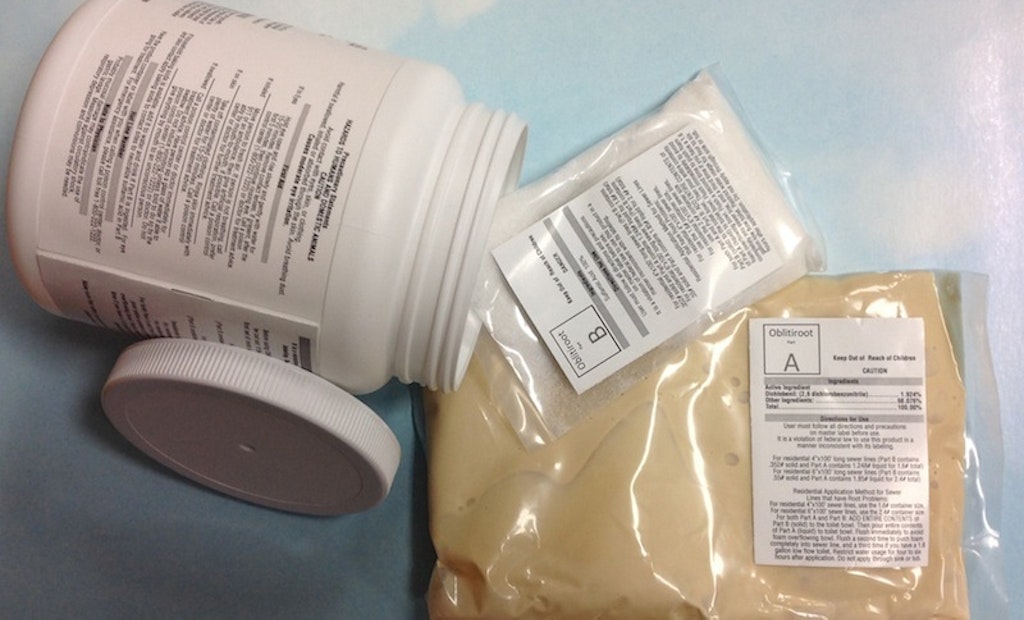

Chemical control options can provide good long-term solutions to root and grease problems in drain and lateral lines. Adding these weapons to your arsenal will give you a more comprehensive set of options for opening clogged lines and keeping them clear.

Root Control...