Sometimes things have different definitions. Take, for example, circuit venting.

Take your pick:

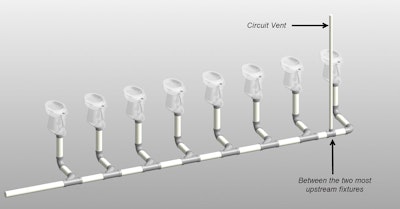

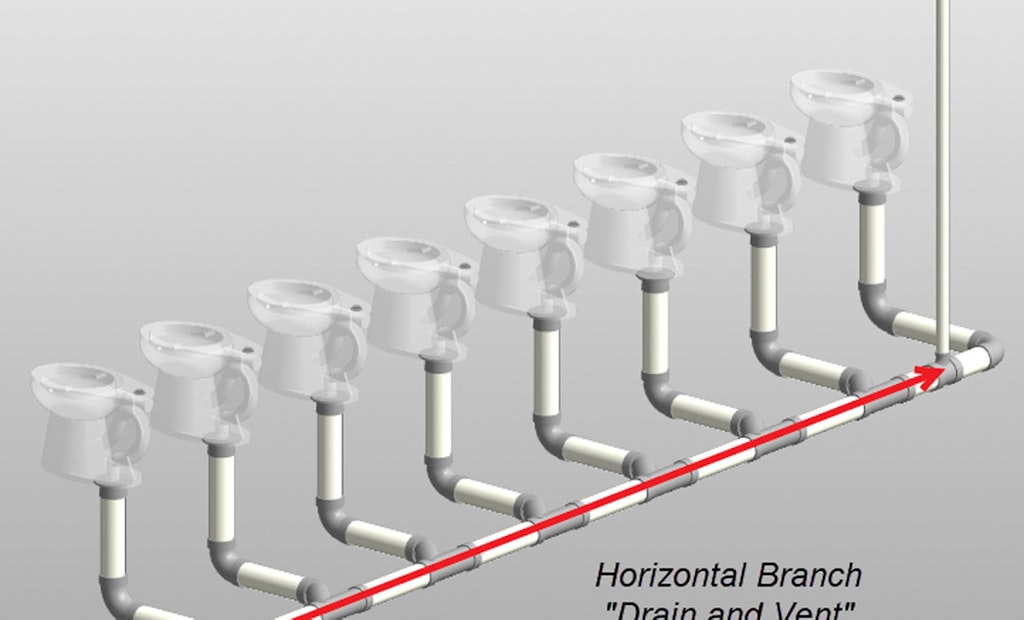

Circuit vent. The vent that connects to a horizontal drainage branch and vents two traps to a maximum of eight traps connected into a battery of fixtures.

Circuit vent means a method...