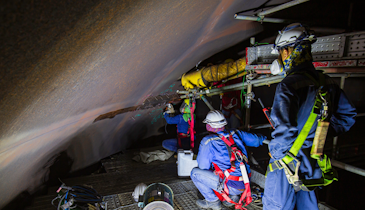

Lawrence Sanchez, TLC Plumbing & Utility technician, installs a hot-water recirculating pump (Taco Comfort Solutions) in a residence near Albuquerque, New Mexico.

It’s not unusual for plumbers to feel uncomfortable about upselling customers on items above and beyond the repair needed. But hot-water recirculating pumps offer an easy win-win situation for both customers and plumbers — as long as it’s an upsell, not a hard sell.

That’s...