Microbiological product reduces pumping costs and frequency

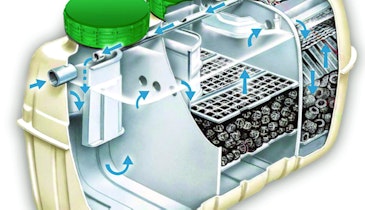

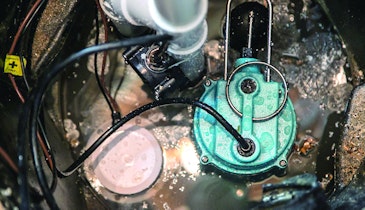

Problem: Five years ago, an Ohio resident spent $430 to have his 1,500-gallon septic tank completely pumped out. This routine maintenance activity had to be performed every two years. Following this schedule, the customer...