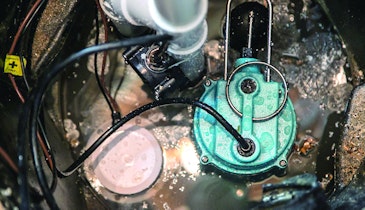

Internal pipe heater prevents shallow septic sewer pipes from freezing

Problem: A shallow septic sewer pipe in a four-season vacation cabin near Gresham, Wisconsin, was freezing due to high-efficiency furnace drainage when the cabin was unoccupied in the winter. This led to messy...