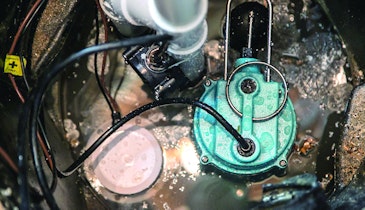

Problem: Ryland Holmes of Virginia Public Works Equipment, a municipal, high-tech and heavy-equipment-needs company, was looking for a better way to clean lift stations. Their customers were struggling with grease problems and needed an effective way to resolve the issues without...