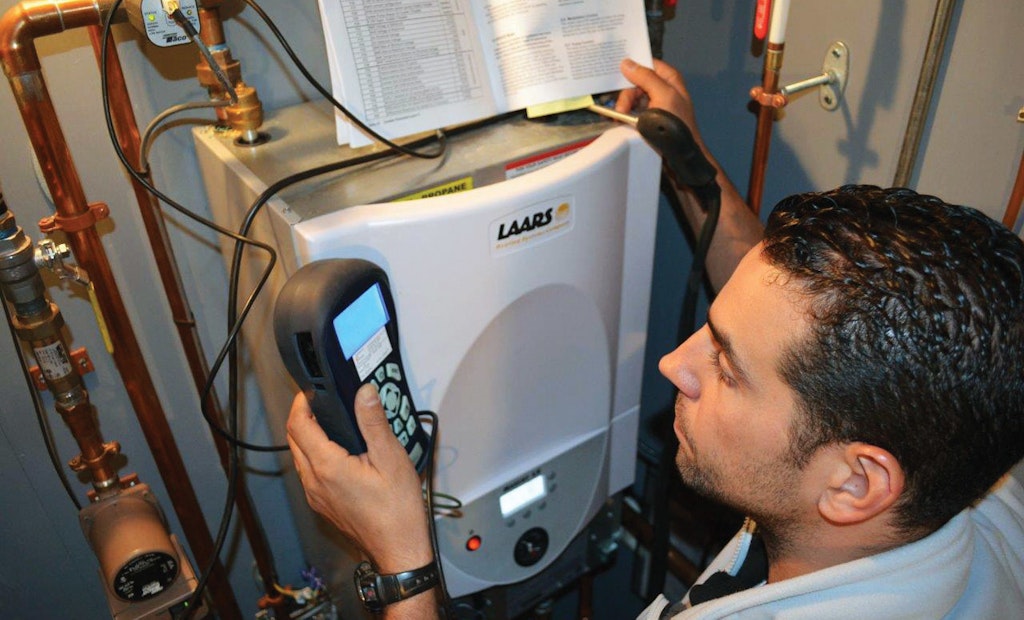

Anthony Tosco, owner of Avanti Plumbing, Heating and Cooling in Audubon, Pennsylvania, uses a combustion tester to measure the combustion efficiency and carbon monoxide levels on a Laars Mascot mod-con boiler.

When master plumber Anthony Tosco installs equipment such as boilers and water heaters, safety — for him, his technicians and his customers — is always top of mind. As such, the owner of Avanti Plumbing, Heating and Cooling swears by the BTU 900 combustion tester made by E...