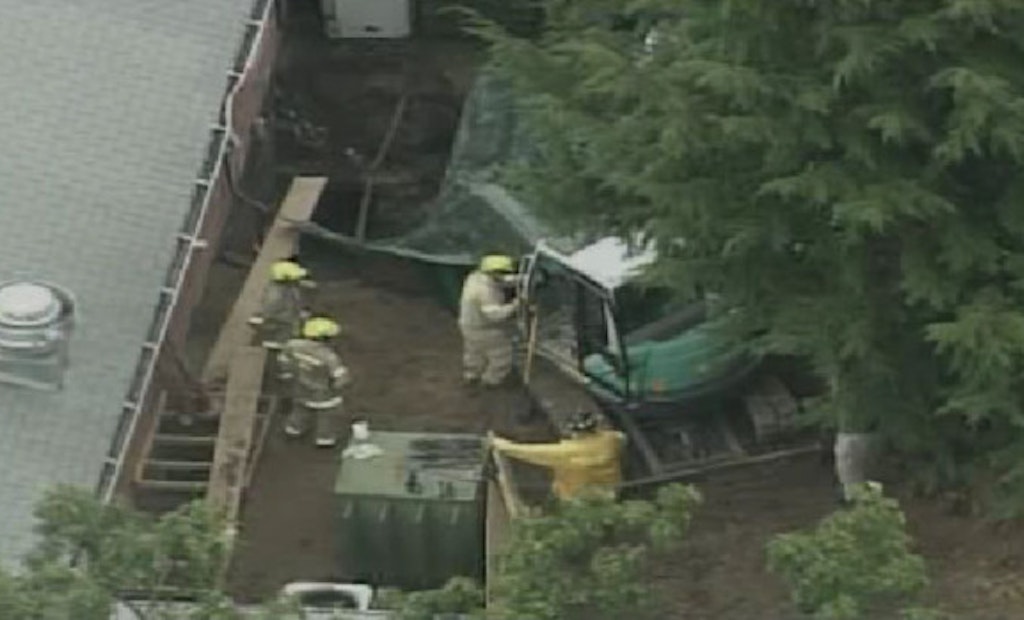

An “unprotected” trench claimed the life of a Rooter-Man employee last month when he went back to pick up a shovel. OSHA said the 10- or 11-foot trench had no shoring or benching with no metal inside.

Jacob Casher was part of a four-man crew relocating sewer lines at a...