Just as a delicious steak is only as good as the quality of the beef and the technique used to cook it, a push-to-connect fitting is only as good as its parts and materials used to make it. Because of this, SharkBite’s product development team works tirelessly to ensure its fittings are made to last.

What makes a SharkBite fitting so secure? It all comes down to what’s inside.

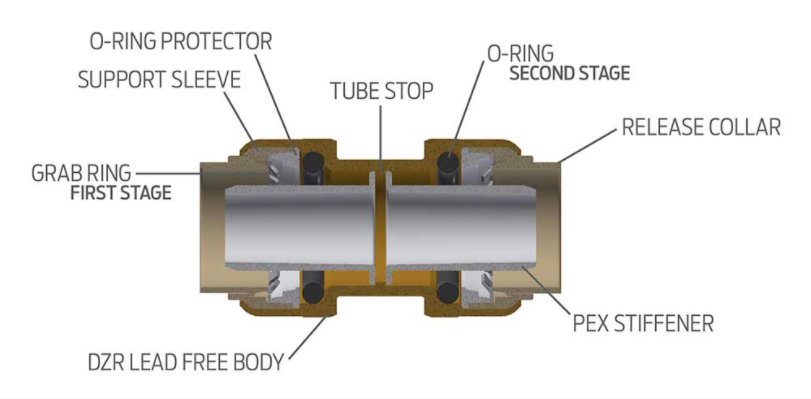

If you took apart a SharkBite fitting, you’d find plumbing parts that help make a three-second connection long-lasting.

Release collar – Once the pipe is inserted into the fitting, it passes through the SharkBite release collar, which is recessed to prevent an accidental release. If you choose to disconnect the fitting to remove or readjust it, you may do so using a disconnect clip or disconnect tongs.

Grab ring – The pipe then passes through the angled 316 stainless steel grab ring, which has teeth that are angled to allow pipe to push through but not pull out. This allows for a tool-free pipe insertion and a strong secure connection.

O-ring and protector – Next, the pipe is aligned with the SharkBite O-ring protector. It then passes through a chloramine-resistant EPDM O-ring that compresses between the pipe and the wall of the fitting before it reaches the tube stop.

Tube stop – Once the pipe reaches the tube stop, a secure connection is made.

PEX stiffener – If you’re using the fitting with PEX, PE-RT or HDPE tubing, the SharkBite stiffener helps keep the O-ring sealed tightly on the outside of the tube.

Body – Each SharkBite fitting’s lead-free dezincification brass makes it strong, corrosion-resistant, durable and compliant with ASSE 1061, NSF/ANSI 61 and NSF/ANSI 372.

Shark marking – On every SharkBite fitting, you’ll see an imprint of a shark on the outside. Make sure to look for the shark on each fitting to ensure you don’t have a FakeBite.

How SharkBite fittings are made

It’s not only the parts inside of a SharkBite fitting that count but also how they are made. Here are a few ways we ensure high quality plumbing parts in our SharkBite manufacturing facility in Cullman, Alabama:

- Manufacturing anomalies – Fully automated systems identify anomalies during the manufacturing process, and we check those systems hourly.

- Quality control – Raw materials and finished products are inspected via cameras, measurement sensors and manually by our team to ensure quality.

- Constant testing – In most cases, our products are tested beyond the industry standards so you can have confidence they’ll last long after installation.

Learn more about our manufacturing process: 4 Ways SharkBite Manages High Product Quality

Why SharkBite fitting parts matter

So why does any of this matter? The reliability of SharkBite products is what helps reduce customer callbacks and gives you confidence every time you make a SharkBite connection. We don’t take lightly your trust in our products, so we do everything we can to maintain a high level of quality control.