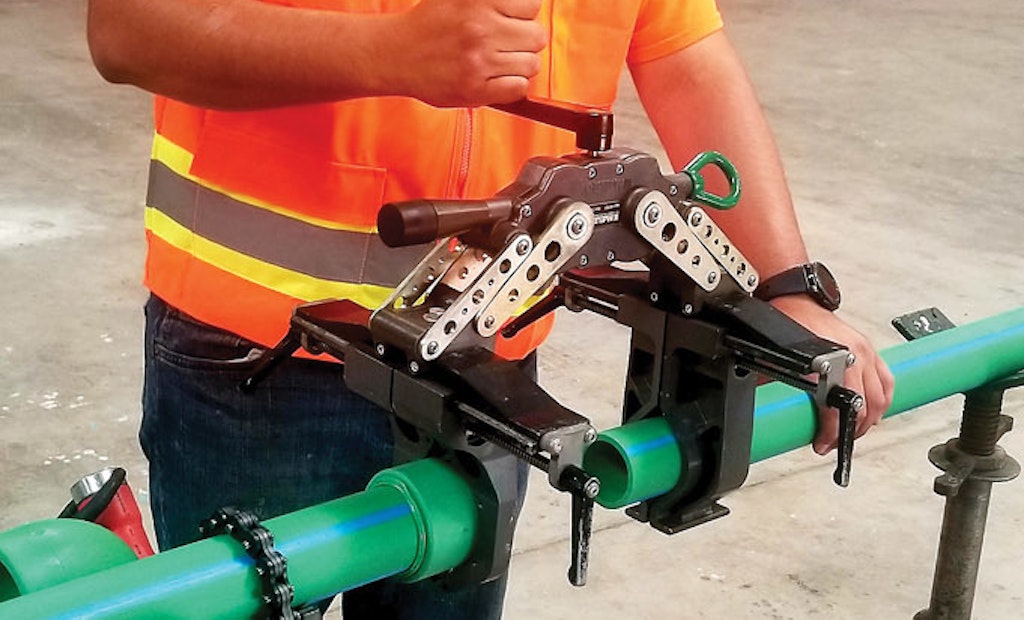

Manny Olivares, Harvey Plumbing technician, fabricates a section of chilled-water piping for a project using the McElroy Spider 125 socket fusion device. It allows the fusion of 2- to 4-inch-diameter polypropylene pipe. (Photo courtesy of Harvey Plumbing Inc.)

When Scott Harvey opted to invest in a McElroy Spider 125 pipe fusion device a couple of years ago, the general manager of Harvey Plumbing made the decision based on a simple equation: One man performing a job site task is better than two.

“It was a no-brainer,” says Harvey of...