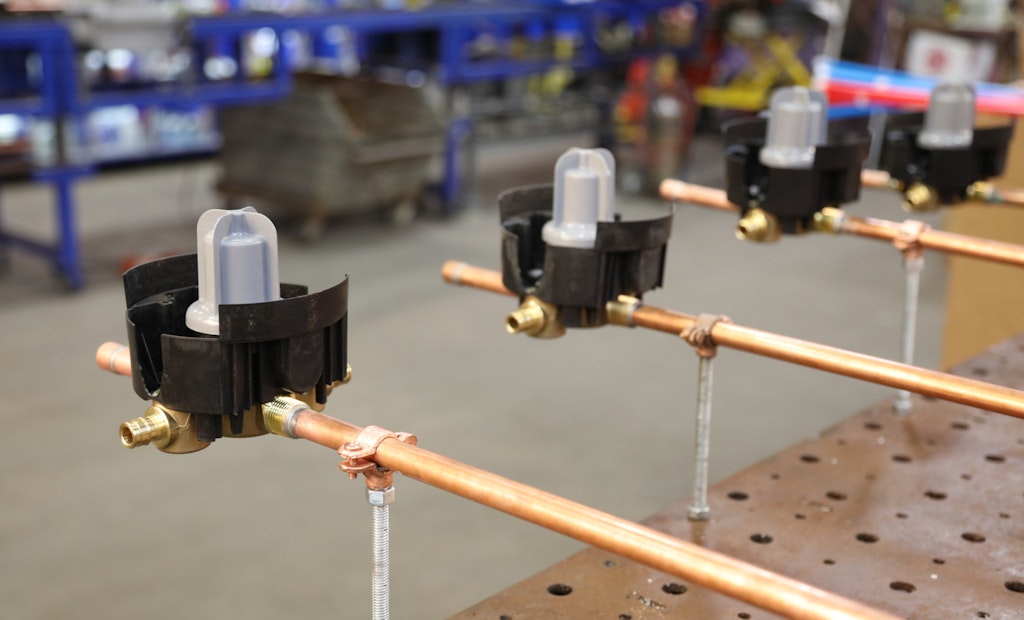

Having one or two workers prefabricate assemblies repeatedly in a controlled workshop environment, as opposed to a variable job site environment, can double or even triple your productivity on projects.

Productivity. It’s the buzzword of the construction industry. With project timelines compressing, budgets tightening, and skilled laborers dwindling by the day, productivity is the difference between a company that thrives and a company that fails.

Because doing more with less...