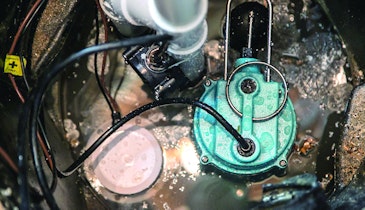

Miller’s Services’ technicians Kenney Boyette, right, and Pierce Rained, left, replace pipe on the air pump from a septic system in hopes of repairing it. The company not only does plumbing service work, but also handles septic tank installation and pumping.

Some contractors like to focus on one service and one service only. But Jamie Miller, the co-owner of Miller’s Services, prefers to take a broader approach: Develop an array of services, including plumbing and septic-system maintenance and repairs, and become a one-stop shop for...