If you do an online search for water heater maintenance, the internet provides a homeowner with just enough information to potentially get themselves in trouble, burn out an electric element, or cause a minor flood. It’s basically a marketing pitch telling your customers not to...

Give Your Customers Boiler and Water Heater Peace of Mind

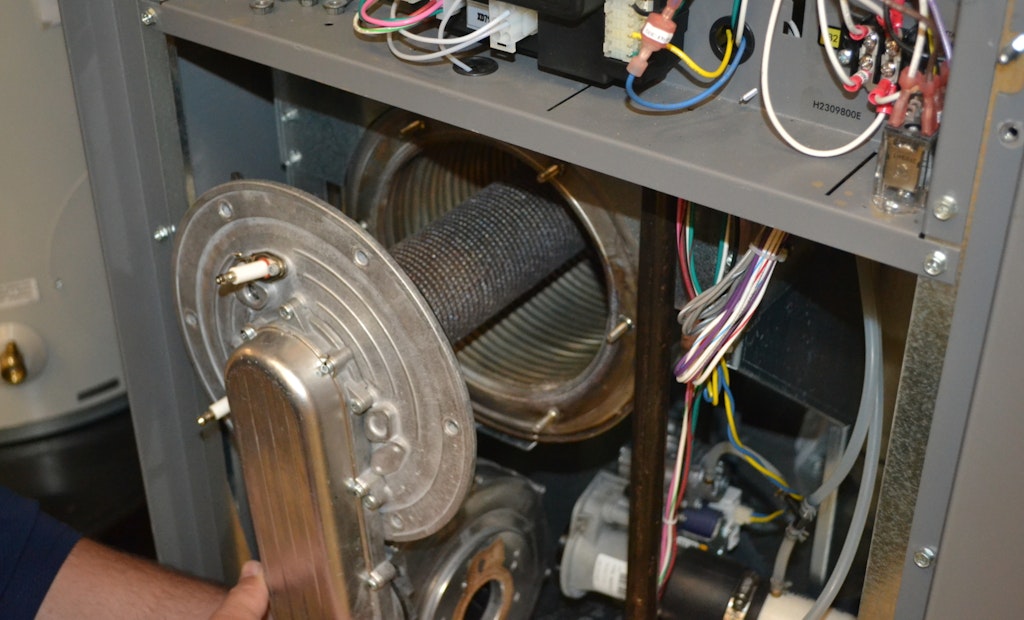

As the cold of winter sets in, your customers are going to want to make sure their boilers and water heaters won’t fail them soon. Here are some maintenance tips to keep in mind for your service calls.

Popular Stories

Discussion

Comments on this site are submitted by users and are not endorsed by nor do they reflect the views or opinions of COLE Publishing, Inc. Comments are moderated before being posted.